VAAPI

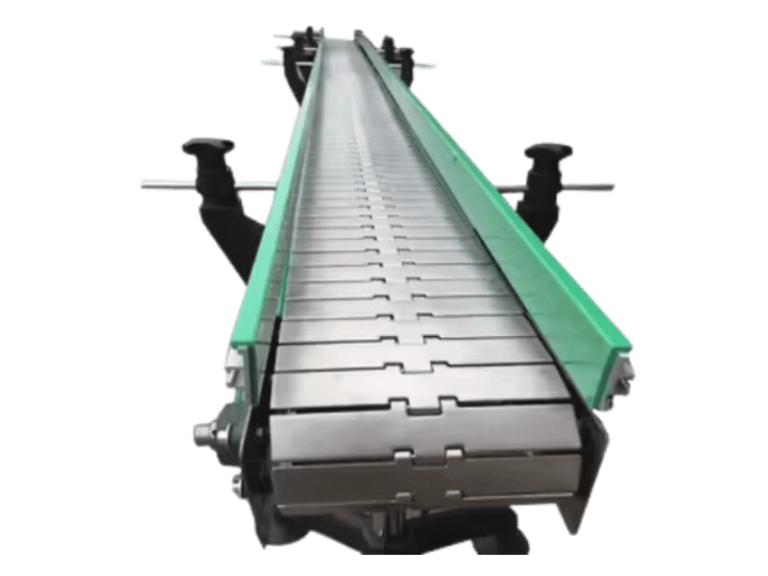

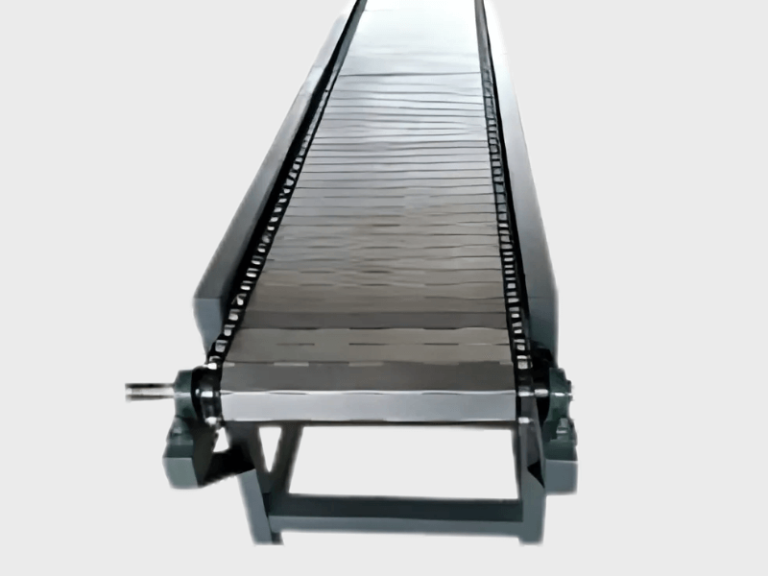

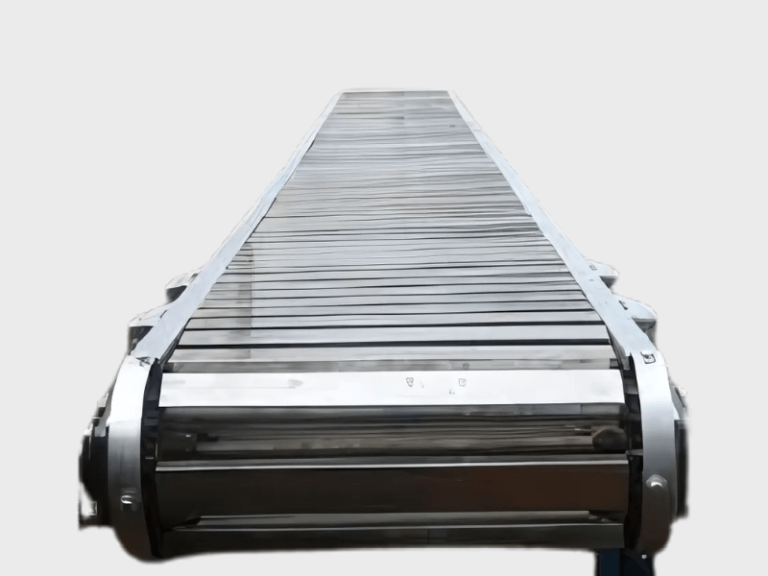

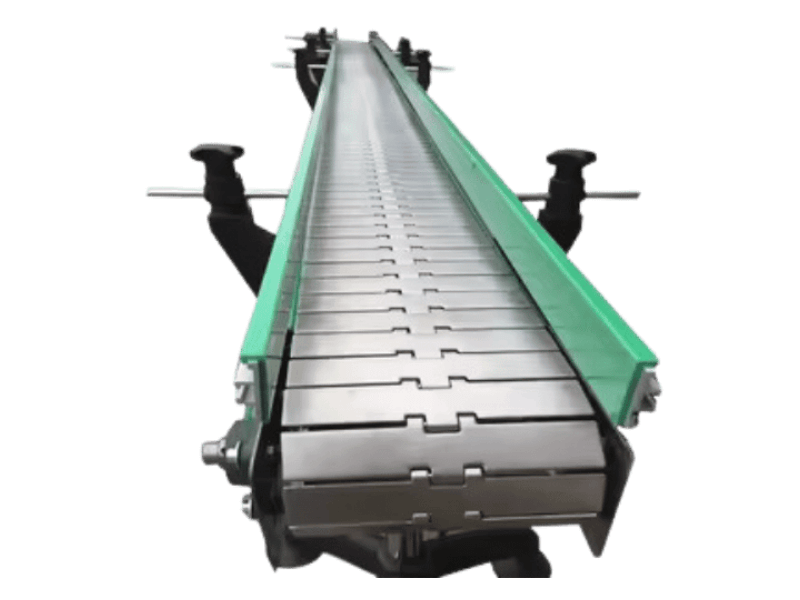

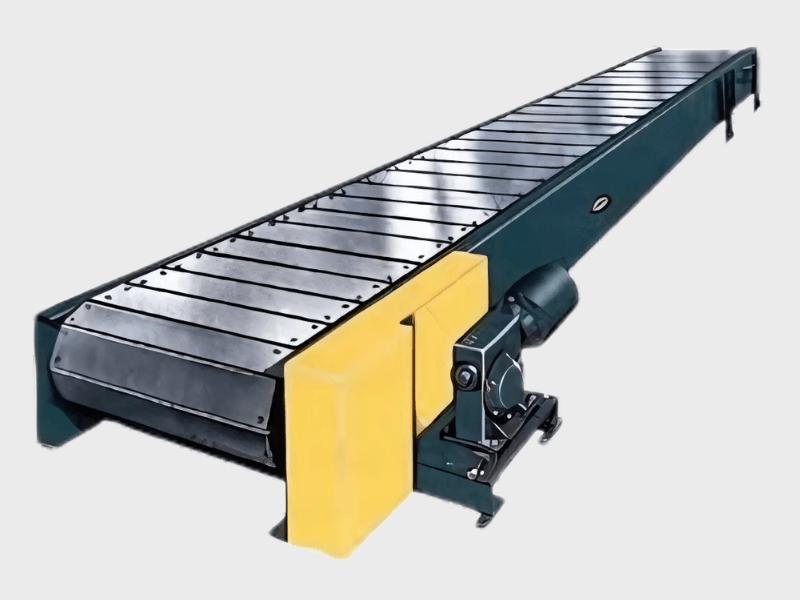

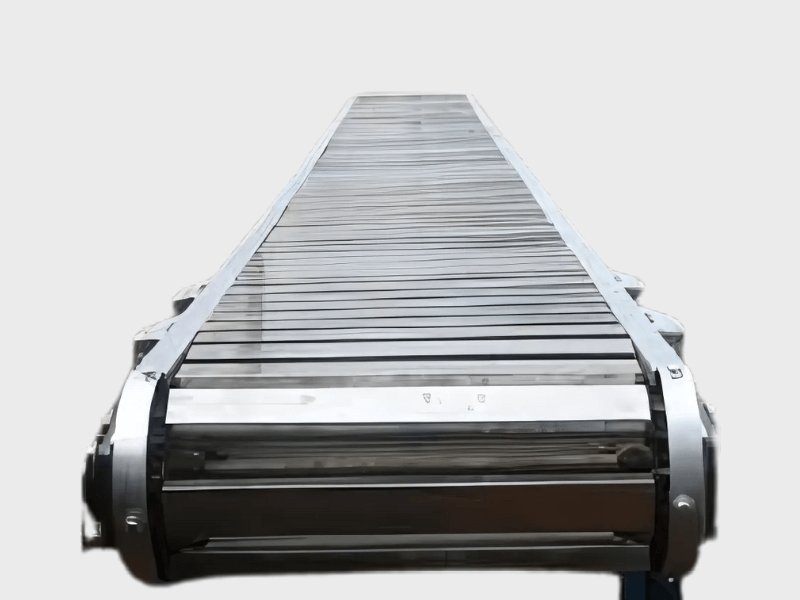

Chain Conveyor Systems

Vaapi Technologies is a reliable industry leader for intralogistics and automation technology. We provide users with cutting-edge, advanced solutions while still prioritizing long-term sustainability.

Chain Conveyor Systems

Vaapi Technologies is a trusted leader in intralogistics and automation, dedicated to delivering cutting-edge solutions with sustainability at the forefront. Through extensive research, rigorous testing, and in-depth logistical analysis, we proudly introduce our latest innovation for the logistics and supply chain sector—ZedSort, a high-speed cross-belt loop sorter.

Features of Chain Conveyor Systems

Durable Construction

Our chain conveyors are built with premium materials, ensuring long-term durability and resistance to wear and tear.

- Built with high-quality materials to withstand heavy-duty applications.

- Suitable for transporting pallets, containers, and other bulk loads.

- Constructed with high-strength materials to handle extreme demands.

- Engineered to resist wear and tear, ensuring long-lasting performance.

- Operating in harsh industrial environments without compromising functionality.

- Designed to handle continuous heavy-duty cycles with minimal degradation.

- Corrosion-resistant coatings available for extended life in specific applications.

MODULAR DESIGN

- Customizable configurations to fit diverse operational requirements.

- Easy to expand and integrate with existing systems.

- Modular sections allow for easy installation and reconfiguration.

- Compatible with various add-ons like diverters and stoppers.

- Facilitates quick upgrades to meet growing business demands.

- Compact design ensures effective use of floor space.

- Flexible layout options make it adaptable to unique facility requirements.

ENERGY-EFFICIENT DRIVE

- Equipped with advanced drive systems for smooth and consistent operation.

- Low power consumption while maintaining reliable performance.

- Incorporates advanced motors for optimized power usage.

- Reduces heat generation, enhancing overall system lifespan.

- Smooth acceleration and deceleration minimize energy spikes.

- Smart control systems adjust speed based on operational needs.

- Environmentally friendly, aligning with sustainable practices.

VERSATILE APPLICATIONS

- Ideal for industries such as manufacturing, warehousing, and logistics.

- Handles a variety of goods with different weights and dimensions.

- Suitable for high-capacity warehouses and manufacturing plants.

- Handles fragile items with precision and care.

- Ideal for transporting irregularly shaped goods without disruptions.

- Operates seamlessly across both straight and curved conveyor layouts.

- Supports integration with automated sorting and scanning systems.

LOW MAINTENANCE

- Robust components reduce the need for frequent repairs.

- Simple maintenance ensures minimal downtime and improved productivity.

- Durable chains and bearings reduce the need for frequent replacements.

- Easy-to-access components simplify inspection and servicing.

- Built-in lubrication systems enhance performance and reduce wear.

- Designed for quick part replacement to minimize downtime.

- Comprehensive support and spare parts availability ensure smooth operations.

Chain Conveyor Specifications

| Parameter | Details |

|---|---|

| Applications | Conveying and Storage |

| Effective Sizes | 2″ to 4″ Pitch Chain |

| Equipment Type | Universal Chain Conveyor |

| Industries Catered | Oil Industry, Gas Fillers, and various other sectors |

| Materials Conveyed | Gas Cylinders, Bottles, Drums |

| Method | Mechanized |

Image Gallery

Trusted by industry leaders who rely on our advanced automation solutions for success.