VAAPI

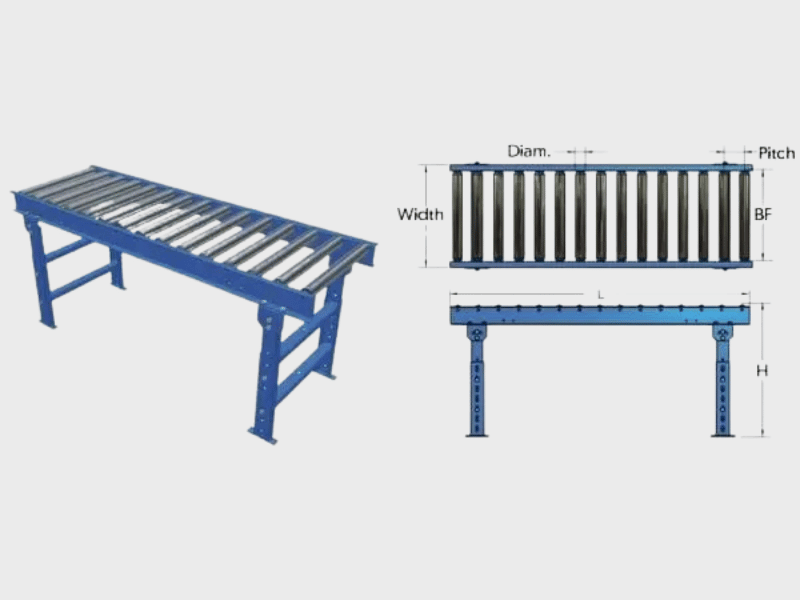

Gravity Roller Conveyor

Vaapi Technologies is a trusted leader in intralogistics and automation. We offer advanced and innovative solutions while focusing on long-term sustainability.

Gravity Roller Conveyor

Vaapi Technologies is a trusted name in intralogistics and automation, focused on providing advanced solutions with sustainability in mind. With thorough research and testing, we are excited to introduce our latest innovation for the logistics and manufacturing industry—the Gravity Roller Conveyor, designed for efficient, cost-effective material handling and smooth operational flow.

Features of Gravity Roller Conveyor

RUGGED CONSTRUCTION FOR DURABILITY

- Heavy-duty galvanized or stainless-steel rollers for extended durability.

- Reinforced frame structure to endure high-load capacities.

- High-impact resistance, designed for repetitive use in busy operations.

- Anti-corrosion coating ensures longevity in humid or outdoor environments.

- Precision-aligned components minimize wear and ensure smooth operation.

SMART MODULAR DESIGN

- Interlocking sections for seamless scalability and reconfiguration.

- Adjustable roller width to accommodate diverse product sizes.

- Modular units integrate with additional systems like motorized conveyors or sorting equipment.

- Compact, space-saving design ideal for facilities with limited floor area.

- Versatile slope options to control flow speed based on product requirements.

ENERGY-FREE AND SUSTAINABLE

- Operates entirely on gravity, requiring no external power source.

- Friction-optimized rollers maximize load movement efficiency with minimal effort.

- Energy-neutral design aligns with green initiatives in logistics and manufacturing.

- Reduces operational costs by eliminating electricity usage.

- Suitable for eco-conscious organizations aiming to lower carbon emissions.

WIDE APPLICATION SCOPE

- Perfect for assembly lines, shipping areas, and order-picking zones.

- Effective for lightweight and medium-weight items like cartons, crates, and totes.

- Ideal for transferring goods in small-to-medium warehouses or retail stores.

- Supports industries like e-commerce, FMCG, and automotive components.

- Excellent for buffering and accumulation during manual or automated processes.

HASSLE-FREE MAINTENANCE

- Minimal components reduce the need for frequent repairs or servicing.

- Easy-to-clean rollers and frames for smooth, uninterrupted performance.

- Quick assembly and disassembly simplify part replacements.

- Long-lasting bearings and rollers enhance reliability and operational uptime.

- Low-cost upkeep ensures maximum ROI over the product’s lifecycle.

Gravity Roller Conveyor Specifications

| Parameter | Details |

|---|---|

| Applications | Material Transfer, Packaging, Assembly, and Storage |

| Effective Sizes | Customizable to operational dimensions |

| Equipment Type | Gravity Roller Conveyor |

| Industries Catered | Warehousing, Manufacturing, E-commerce |

| Materials Conveyed | Cartons, Crates, Totes, Lightweight Bulk Items |

| Method | Gravity-driven for efficient material flow |

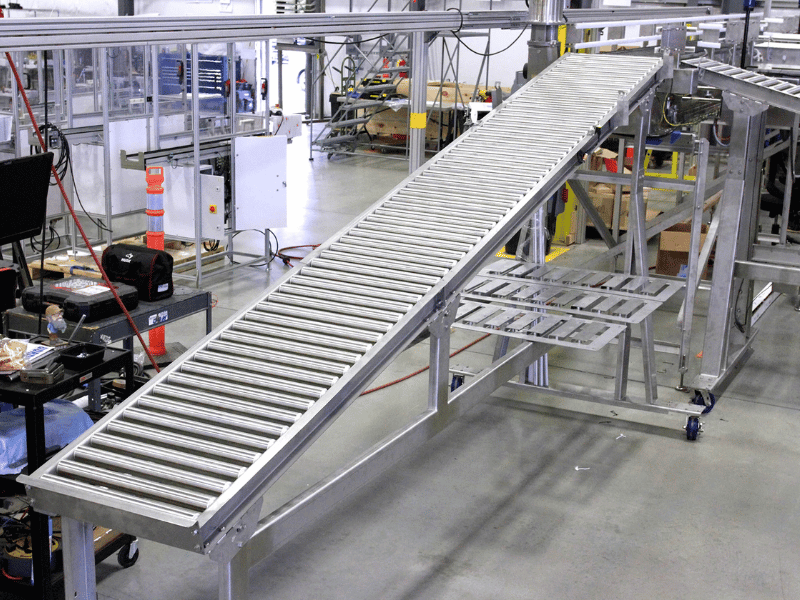

Image Gallery

Trusted by industry leaders who rely on our advanced automation solutions for success.