VAAPI

Reverse Engineering

Vaapi Technologies is a trusted leader in intralogistics and automation. We offer advanced and innovative solutions while focusing on long-term sustainability.

Reverse Engineering

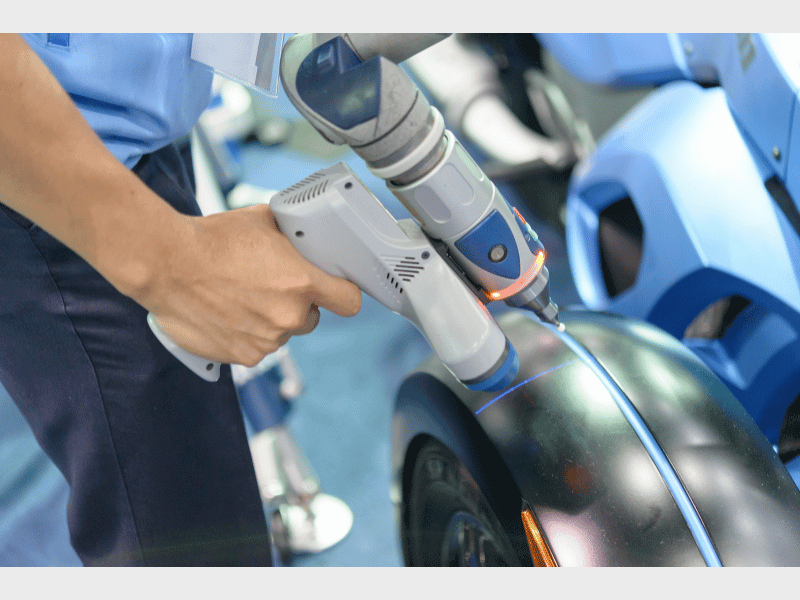

Reverse Engineering Services provide a detailed analysis and recreation of existing components, products, or systems to unlock new possibilities in design and functionality. By leveraging advanced scanning, modeling, and simulation tools, these services are ideal for redesigning, improving, or replicating parts. Industries such as automotive, aerospace, and manufacturing benefit greatly from reverse engineering to innovate and optimize their operations.

Features of Reverse Engineering

HIGH-PRECISION DATA CAPTURE

- Utilizes advanced 3D scanning and measurement tools for accurate data collection.

- Captures intricate geometries, internal structures, and surface details.

- Ensures minimal deviation between original and recreated components.

- Handles a wide range of materials, from metals to plastics and composites.

- Suitable for parts with complex or organic shapes.

RELIABLE DESIGN REPLICATION

- Recreates discontinued or legacy components with precision.

- Generates CAD-ready models from physical parts for further modifications.

- Enables seamless integration with existing systems or assemblies.

- Facilitates the restoration of worn or damaged parts to original specifications.

- Produces functional prototypes for performance testing and validation.

TIME-EFFICIENT AND NON-CONTACT PROCESS

- Identifies design inefficiencies for performance improvement.

- Allows material substitution for cost reduction or enhanced durability.

- Supports structural analysis and load testing for critical applications.

- Optimizes weight, strength, and durability of components.

- Aids in developing innovative designs based on existing concepts.

COST-EFFECTIVE SOLUTIONS

- Reduces dependency on original manufacturers for spare parts.

- Lowers production costs by eliminating the need for new tooling.

- Speeds up development cycles with efficient data processing.

- Minimizes waste by reusing and improving existing designs.

- Saves resources by addressing design flaws before mass production.

SEAMLESS INTEGRATION WITH CAD TOOLS

- Converts scanned data into editable CAD files for modifications.

- Provides compatibility with popular software like SolidWorks, AutoCAD, and CATIA.

- Supports 2D and 3D model generation for documentation and manufacturing.

- Facilitates rapid prototyping through integration with 3D printing workflows.

- Ensures high-quality output ready for production or simulation.

about Reverse Engineering

| Parameter | Details |

|---|---|

| Data Collection | 3D Scanning, CT Scans, and Coordinate Measuring Machines (CMM) |

| Applications | Part Replication, Design Optimization, Legacy Component Recreation |

| Industries Catered | Automotive, Aerospace, Healthcare, Manufacturing, Consumer Goods |

| Output Formats | STL, STEP, IGES, and 3D CAD Models |

| Accuracy | Up to ±0.01 mm (Depending on Scanning Technology) |

| Software Compatibility | SolidWorks, AutoCAD, CATIA, Creo |

Image Gallery

Trusted by industry leaders who rely on our advanced automation solutions for success.