VAAPI

Robotic Pick & Place

Vaapi Technologies is a trusted leader in intralogistics and automation. We offer advanced and innovative solutions while focusing on long-term sustainability.

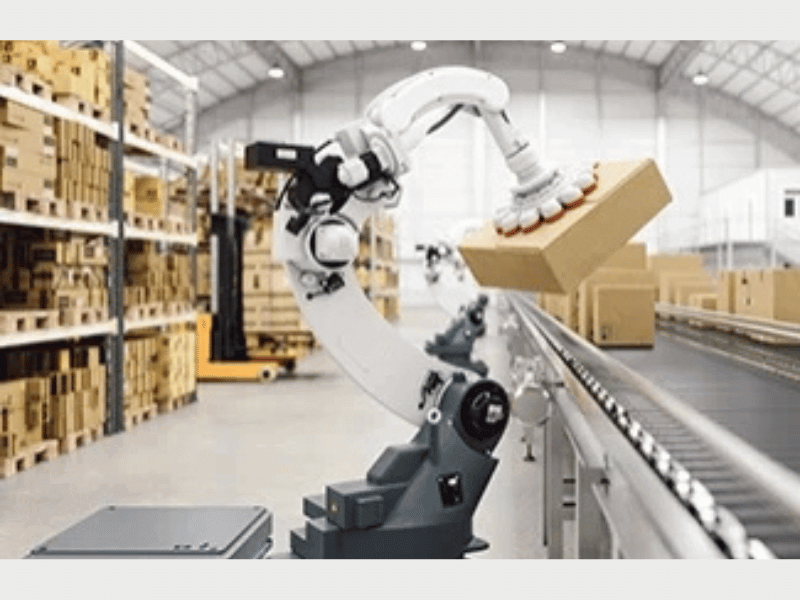

Robotic Pick & Place

The Robotic Pick & Place system is a cutting-edge automation solution designed to enhance precision, efficiency, and speed in material handling tasks. Equipped with advanced sensors and robotics, it effortlessly picks, sorts, and places items with unmatched accuracy. Ideal for diverse industries, it optimizes workflows and reduces manual effort, ensuring higher productivity.

Features of Robotic Pick & Place

HIGH PRECISION AND SPEED

- Advanced robotic arms equipped with high-resolution sensors for precise picking and placement.

- Capable of handling delicate and high-speed operations with accuracy.

- Quick and repeatable actions ensure consistent performance in demanding tasks.

- Reduces errors and improves quality control in production and assembly lines.

FLEXIBLE AND ADAPTABLE DESIGN

- Configurable to handle a variety of products, shapes, and weights.

- Supports diverse end-of-arm tools like suction grippers, mechanical clamps, and magnetic heads.

- Easily integrates into existing workflows and systems.

- Programmable to adapt to new tasks or operational changes.

- Compact and modular design saves space and allows easy reconfiguration.

DURABLE AND RELIABLE BUILD

- Built with industrial-grade materials for long-lasting performance.

- Designed to withstand continuous use in challenging environments.

- High-strength robotic components minimize wear and tear.

- Reliable operation ensures minimal downtime in high-demand workflows.

- Enclosed systems protect sensitive components from dust and debris.

ENHANCED AUTOMATION AND INTELLIGENCE

- Powered by advanced AI and machine learning for dynamic task handling.

- Vision systems enable object recognition, tracking, and sorting.

- Adaptive programming adjusts movements based on real-time inputs.

- Ideal for repetitive tasks like picking, placing, sorting, and assembly.

- Enhances operational efficiency by automating complex processes.

LOW MAINTENANCE AND COST-EFFECTIVE

- Long operational life reduces frequent replacement costs.

- Minimal maintenance requirements ensure cost efficiency.

- Remote diagnostics and monitoring for proactive servicing.

- Easy-to-replace components minimize downtime during repairs.

- High ROI through reduced labor costs and increased output.

Robotic Pick & Place Specifications

| Parameter | Details |

|---|---|

| Applications | Picking, Placing, Sorting, Assembly, and Packaging |

| Effective Sizes | Customizable robotic arms to fit operational requirements |

| Equipment Type | Robotic Pick & Place System |

| Industries Catered | Manufacturing, E-commerce, Pharmaceuticals, FMCG, and Automotive |

| Materials Handled | Cartons, Crates, Delicate Items, Components, and Bulk Products |

| Method | AI-powered robotic arms with vision systems |

Image Gallery

Trusted by industry leaders who rely on our advanced automation solutions for success.