VAAPI

Robotic Welding

Vaapi Technologies is a trusted leader in intralogistics and automation. We offer advanced and innovative solutions while focusing on long-term sustainability.

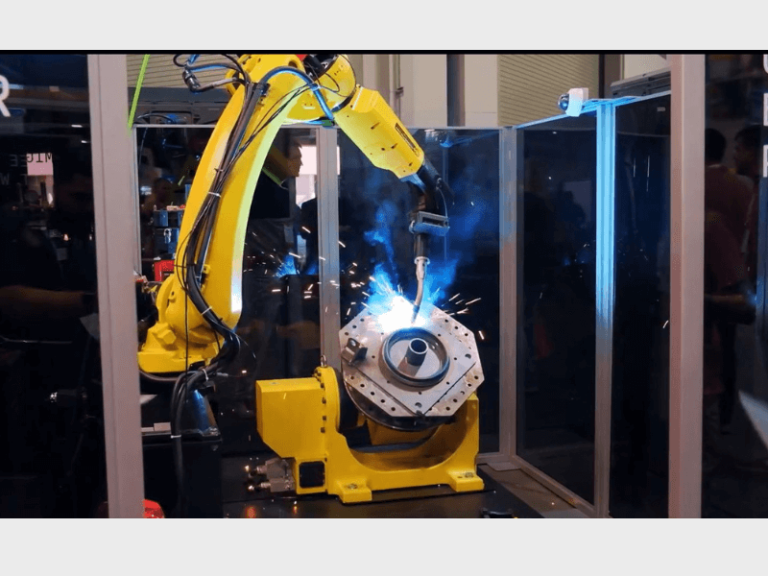

Robotic Welding

The Robotic Welding is an innovative material handling solution designed for efficient movement of goods through complex layouts. With its smooth curves and adaptable design, it allows seamless transitions in confined spaces. Ideal for industries with intricate workflows, it enhances productivity while optimizing floor space utilization.

Features of Robotic Welding

PRECISE AND CONSISTENT WELDING

- Delivers accurate and repeatable welds with minimal deviations.

- Advanced sensors and control systems ensure optimal weld quality.

- Ideal for complex geometries and high-speed welding requirements.

- Reduces defects, enhancing product quality and reliability.

- Consistent performance in high-volume production environments.

AUTOMATED AND SCALABLE OPERATIONS

- Fully automated workflows reduce manual labor and human error.

- Programmable for various welding types, including MIG, TIG, and spot welding.

- Easily scalable for small-batch or mass-production setups.

- Supports multi-axis movement for handling intricate designs.

- Integrates seamlessly with existing manufacturing systems.

ROBUST AND DURABLE CONSTRUCTION

- Built with industrial-grade materials for long-lasting performance.

- Capable of withstanding high temperatures and demanding environments.

- Reinforced robotic arms ensure stability and precision during operations.

- Reliable components minimize wear and extend operational life.

- Engineered for 24/7 usage in rigorous workflows.

ENERGY-EFFICIENT AND COST-EFFECTIVE

- Optimized power usage reduces energy consumption and operational costs.

- Increases productivity by reducing cycle times and improving throughput.

- Reduces waste of welding materials through precision application.

- High ROI through minimal downtime and increased output.

- Ideal for businesses seeking sustainable manufacturing practices.

ENHANCED SAFETY AND MAINTENANCE

- Reduces human exposure to hazardous fumes, sparks, and high temperatures.

- Advanced safety systems include emergency stops and collision detection.

- Simplified maintenance through modular components and remote diagnostics.

- Long-lasting sensors and welding tips minimize frequent replacements.

- Minimizes risks and ensures compliance with workplace safety standards.

Robotic Welding Specifications

| Parameter | Details |

|---|---|

| Applications | Welding Frames, Panels, Components, and Structural Assemblies |

| Effective Sizes | Customizable robotic arms for various welding ranges |

| Equipment Type | Robotic Welding System |

| Industries Catered | Automotive, Aerospace, Construction, and Heavy Machinery |

| Welding Types | MIG, TIG, Spot, and Arc Welding |

| Method | AI-controlled robotic arms with advanced sensor systems |

Image Gallery

Trusted by industry leaders who rely on our advanced automation solutions for success.