VAAPI

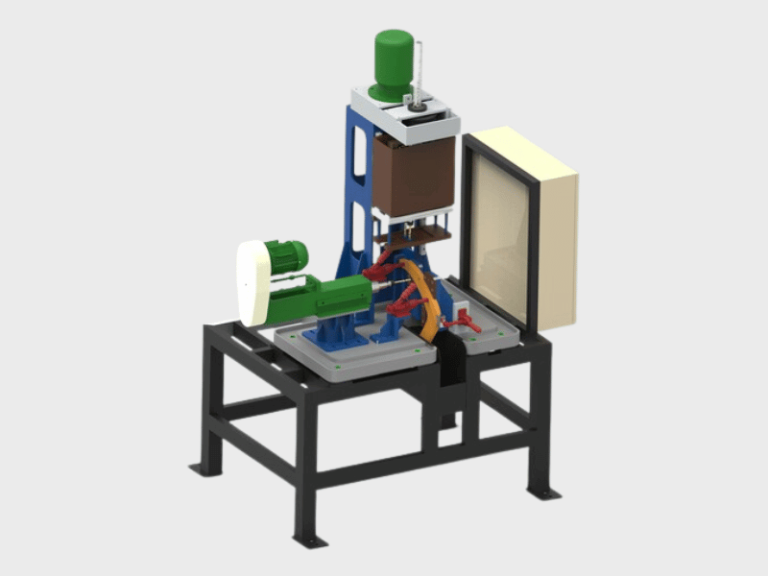

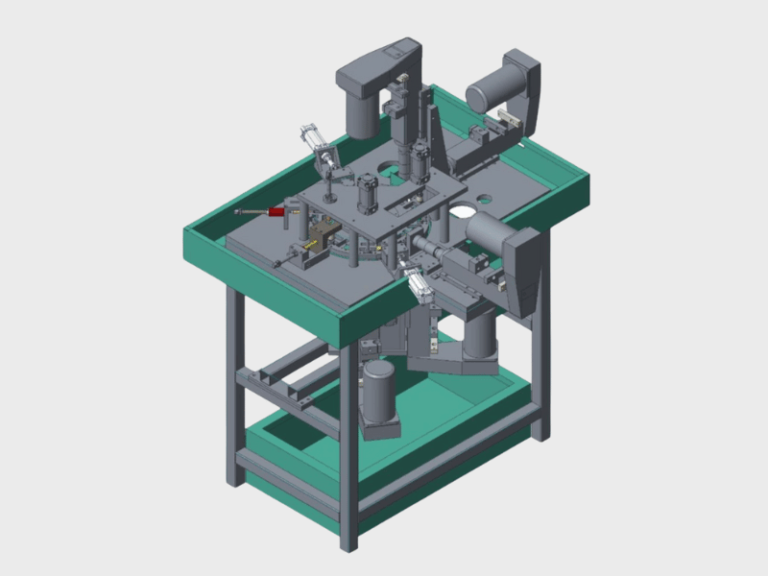

SPM Machine

Vaapi Technologies is a trusted leader in intralogistics and automation. We offer advanced and innovative solutions while focusing on long-term sustainability.

SPM machine

Special Purpose Machines (SPMs) are tailor-made solutions designed to perform specific tasks with high efficiency and precision. Built to handle complex and repetitive operations, SPMs optimize production workflows, reduce human intervention, and ensure consistent output quality. They are the backbone of modern manufacturing, enhancing productivity and minimizing operational costs.

Features of spm machine

CUSTOMIZED FOR SPECIFIC TASKS

- Designed to meet unique operational requirements and industrial needs.

- Tailor-made configurations for applications like drilling, welding, assembly, and inspection.

- Capable of handling intricate, repetitive, or high-precision processes.

- Supports automation for seamless integration with existing workflows.

- Ideal for industries requiring specialized equipment for production efficiency.

HIGH PERFORMANCE AND RELIABILITY

- Precision engineering ensures consistent and accurate output.

- Operates efficiently under high load and continuous use.

- Built with robust components for long-lasting durability.

- Reduces errors and maintains quality consistency in production.

- Enhances throughput in high-demand manufacturing environments.

SCALABLE AND FLEXIBLE DESIGN

- Modular construction allows for future upgrades or reconfiguration.

- Adaptable to various product sizes, shapes, and production needs.

- Can be integrated with robotic arms, conveyors, or inspection systems.

- Suitable for batch production or mass manufacturing setups.

- Compact design saves floor space and optimizes factory layouts.

COST-EFFECTIVE OPERATION

- Reduces labor costs by automating repetitive or complex tasks.

- Minimizes material wastage through precision handling and processing.

- High operational efficiency leads to reduced production cycle times.

- Ensures excellent return on investment over the equipment lifecycle.

- Ideal for industries looking to enhance productivity with minimal expenses.

LOW MAINTENANCE REQUIREMENTS

- Simple and robust design reduces maintenance efforts.

- Easy-to-access components for quick servicing and repairs.

- Reliable performance ensures minimal downtime.

- Long-lasting parts and materials provide a cost-effective solution.

- Advanced monitoring systems enable proactive diagnostics and maintenance.

SPM Machine Specifications

| Parameter | Details |

|---|---|

| Applications | Machining, Assembly, Quality Control, Packaging, and Testing |

| Effective Sizes | Custom-built to match operational requirements |

| Equipment Type | Special Purpose Machine (SPM) |

| Industries Catered | Automotive, Electronics, FMCG, Aerospace, and Heavy Machinery |

| Materials Processed | Metal, Plastic, Composite, and Specialized Components |

| Method | Automated or Semi-automated, Tailored for Specific Operations |

Image Gallery

Trusted by industry leaders who rely on our advanced automation solutions for success.